6491B to BS 7211 (New BS EN 50525-3-41)

Application and Description

These cables are designed for fixed wiring purposes in domestic and industrial power/lighting applications. They can be used in trunking or conduit, or may be surface mounted when used for earthing. and they are generally in areas (such as public and government buildings) where smoke and toxic fumes may cause a threat to life and equipment. The cables produce no corrosive gasses when burnt and which is particularly important where electronic equipment is installed. 6491B is equivalent to harmonized code H07Z-U/ H07Z-R/H07Z-K.

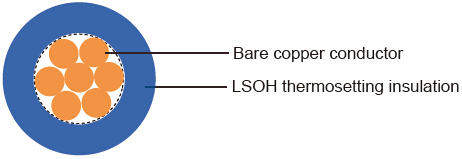

Cable Construction

- - Bare copper made of solid/strands conductor

- - Solid to BS 6360 CL-1 or IEC 60228 CL-1(H07Z-U)

- - Stranding to BS 6360 CL-2 or IEC 60228 CL-2(H07Z-R)

- - Stranding to BS 6360 CL-5 or IEC 60228 CL-5(H07Z-K)

- - LSOH thermosetting core insulation type EI5

Core Identification

Black, Blue, Green/Yellow, Red, Yellow, White, Violet, Brown, Grey, Orange, Pink

Technical Characteristics

- - Working voltage: 450/750v

- - Test voltage: 2500 volts

- - Minimum bending radius: up to 10 mm^2 - 3xoverall diameter; above 25 mm^2 - 6xoverall diameter

- - Operating temperature: +0o C to +90o C

- - Short circuit temperature: +250o C

- - Insulation resistance: 10 MΩxkm

- - Halogen free acc. to EN 50267-2-1 / IEC 60754-1

- - Smoke density acc. to EN 50268-2 / IEC 61034-2

- - Corrosivity of gases acc. to EN 50267-2-2, IEC 60754-2

- - Flame retardancy acc. to EN 50265-2-1, IEC 60332-1

Cable Parameter

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm^2 |

Nominal Thickness of Insulation mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/km |

Nominal Weight kg/km |

| 16(solid) | 1x1.5 | 7 | 2.8 | 14.4 | 20 |

| 14(solid) | 1x2.5 | 8 | 3.3 | 24 | 30 |

| 12(solid) | 1x4 | 8 | 3.8 | 38 | 45 |

| 10(solid) | 1x6 | 8 | 4.3 | 58 | 65 |

| 8(solid) | 1x10 | 10 | 5.5 | 96 | 105 |

| 16(7/24) | 1x1.5 | 0.7 | 3.0 | 14.4 | 21 |

| 14(7/22) | 1x2.5 | 0.8 | 3.6 | 24 | 33 |

| 12(7/20) | 1x4 | 0.8 | 4.1 | 39 | 49 |

| 10(7/18) | 1x6 | 0.8 | 4.7 | 58 | 71 |

| 8(7/16) | 1x10 | 1 | 6 | 96 | 114 |

| 6(7/14) | 1x16 | 1 | 6.8 | 154 | 172 |

| 4(7/12) | 1x25 | 1.2 | 8.4 | 240 | 265 |

| 2(7/10) | 1x35 | 1.2 | 9.3 | 336 | 360 |

| 1(19/13) | 1x50 | 1.4 | 10.9 | 480 | 487 |

| 2/0(19/11) | 1x70 | 1.4 | 12.6 | 672 | 683 |

| 3/0(19/10) | 1x95 | 1.6 | 14.7 | 912 | 946 |

| 4/0(37/12) | 1x120 | 1.6 | 16 | 1152 | 1174 |

| 300MCM(37/11) | 1x150 | 1.8 | 17.9 | 1440 | 1448 |

| 350MCM(37/10) | 1x185 | 2.0 | 20.0 | 1776 | 1820 |

| 500MCM(61/11) | 1x240 | 2.2 | 22.7 | 2304 | 2371 |

| -(61/10) | 1x300 | 2.4 | 25.4 | 2980 | 3050 |

| -(61/9) | 1x400 | 2.6 | 28.8 | 3765 | 3842 |

| -(61/8) | 1x500 | 2.8 | 32.8 | 4725 | 4900 |

| -(127/10) | 1x630 | 2.8 | 36.5 | 6205 | 6334 |

| 16(30/30) | 1 x 1.5 | 7 | 3.5 | 14.4 | 24 |

| 14(50/30) | 1 x 2.5 | 8 | 4 | 24 | 35 |

| 12(56/28) | 1 x 4 | 8 | 4.8 | 38 | 51 |

| 10(84/28) | 1 x 6 | 8 | 6 | 58 | 71 |

| 8(80/26) | 1 x 10 | 10 | 6.7 | 96 | 118 |

| 6(128/26) | 1 x 16 | 10 | 8.2 | 154 | 180 |

| 4(200/26) | 1 x 25 | 12 | 10.2 | 240 | 278 |

| 2(280/26) | 1 x 35 | 12 | 11.5 | 336 | 375 |

| 1(400/26) | 1 x 50 | 14 | 13.6 | 480 | 560 |

| 2/0(356/24) | 1 x 70 | 14 | 16 | 672 | 780 |

| 3/0(485/24) | 1 x 95 | 16 | 18.4 | 912 | 952 |

| 4/0(614/24) | 1 x 120 | 16 | 20.3 | 1152 | 1200 |

| 300 MCM (765/24) | 1 x 150 | 18 | 22.7 | 1440 | 1505 |

| 350 MCM (944/24) | 1 x 185 | 20 | 25.3 | 1776 | 1845 |

| 500MCM(1225/24) | 1 x 240 | 22 | 28.3 | 2304 | 2400 |